Corrugated Pipe Machine

Home » Corrugated Pipe Machine

Customised Corrugated Pipe Machine

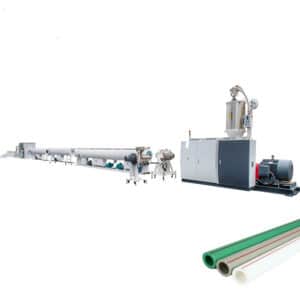

Corrugated Pipe Machines are used to produce corrugated pipes made of PE, PP, EVA, PVC and PA with a precision of 9 mm to 1200 mm and are used in a wide range of industries because of their high strength and flexibility. The correct choice of corrugated pipe production line is therefore extremely important for your business development.

Types of Corrugated Pipe Machine

We have two types of corrugated pipe lines (single-wall and double-wall) which are tailored to the specific application of the corrugated pipe, mainly for single-wall corrugated pipes (SWC pipes) with a smooth interior and double-wall corrugated pipes (DWC pipes) with a smooth interior on both sides. The double-wall corrugated pipe (DWC pipes) is custom designed for corrugated pipes that are smooth on both sides. This depends on the specific application of the corrugated pipe.

A .Single wall corrugated pipe machine

Single wall corrugated pipe machine is mainly used for the production of corrugated pipe products with both internal and external corrugations. The machine structure is closed and has a special screw and mould design inside, a sandwich design for the forming tunnel and cold water cooling during the production process. The single-wall corrugated pipe production line is characterised by low wear and tear, easy material forming, fast production line speed, stable operation and simple control and easy operation. The corrugated pipes produced are resistant to high temperatures, corrosion, abrasion and high strength. As a result, these pipes are widely used in the fields of electrical threading pipes, automobile threading pipes, household appliances, municipal drainage, agricultural irrigation and so on. It has great market potential.

Model |

Pipe diameter |

Extruder model |

Motor powe |

Production speed |

Mold pairs |

Vacuum pump (Option) |

|---|---|---|---|---|---|---|

SJ-14 |

5-14mm |

SJ-45 |

11KW |

6-8m/min |

42 |

1.5KW |

SJ-32 |

10-32mm |

SJ-50 |

15KW |

5-12m/min |

50 |

1.5kw |

SJ-50 |

16-50mm |

SJ-65 |

30KW |

3-10m/min |

50 |

2.2KW |

SJ-63 |

16-63mm |

SJ-65 |

30KW |

3-10m/min |

50 |

2.2KW |

SJ-110 |

32-110mm |

SJ-75 |

37KW |

3-6m/min |

72 |

5.5KW |

B .Double wall corrugated pipe machine

Double wall corrugated pipe machine is mainly used to produce double-walled corrugated pipe, because of corrosion resistance, wear resistance, high strength, flexibility and other characteristics, is now widely used in highway, slope, golf course and other heavy load situations such as drainage, permeability; municipal sewage; communication, power supply cable casing. The double-walled corrugated pipe production line adopts double-layer spiral extrusion die head, the forming machine adopts vacuum environment, the pipe making quality is higher, and is equipped with aluminium mould forming cooling system + water condensation cooling system, which greatly enhances the cooling efficiency. And combined with our self-developed corrugated pipe extrusion die. The corrugated pipe production line is characterised by high output and low energy consumption. It can be used for a wide range of diameters such as large diameter as well as small diameter.

Model |

Pipe diameter |

Production speed |

Extruder model |

Motor poweR |

|---|---|---|---|---|

SBWG-250 |

75-250mm |

1.5-4m/min |

75/33&65/33 |

55kw&45kw |

SJSBWG-50 |

32-50mm |

4-5m/min |

65/30 &50/30 |

30kw & 15kw |

SJSBWG-110 |

50-110mm |

3-4rm/min |

65/33&65/30 |

37kw & 30kw |

SJSBWG-160 |

75-160mm |

2-3.5m/min |

75/30&65/30 |

45kw& 30kw |

Corrugated Pipe Machine components

Предлагаются два типа экструдеров (конический двухшнековый экструдер и но шнековый экструдер), причем для разных материалов труб могут использоваться разные типы экструдеров.

В основном используется для формовки труб, системы охлаждения алюминиевых форм + системы охлаждения водяного конденсата.

Заготовка выдавливается из экструдера через внутреннее и внешнее отверстие головки двустенной трубы.

Полная обработка и формовка труб с использованием вакуумной технологии в штампе

Охлаждающий бак из нержавеющей стали марки 304 для вторичного охлаждения и придания формы трубе (специально для линии по производству двустенных гофрированных труб)

Высокоточный отрезной станок для точной резки прямых и развальцованных труб с устройством запуска резки

Штабелер с автоматической разгрузкой, с системой взвешивания (линия по производству двустенных гофрированных труб)

Автоматическая перемоточно-обвязочная машина для одностенных/двустенных гофрированных труб с автоматической перемоткой и обвязкой (возможна установка одной и двух станций)

Машина для пробивки гофрированных труб с двойными стенками для пробивки труб (оснащена автоматической системой управления для достижения автоматической перемотки и пакетирования)

The production process of corrugated pipe

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder for PE/PP material/double screw extruder for PVC material→ pipe extrusion die + corrugated pipe forming die→ forming machine→ haul off machine → cutting machine

What are the uses of corrugated pipe?

Corrugated pipe is extremely flexible and HDPE is recognized as the most versatile, flexible, durable and long-lasting corrugated pipe material among the different types of corrugated pipe. Because HDPE is lightweight and unbreakable, it has excellent transportation and installation characteristics, making it widely used in underground structures for applications such as subsurface drainage, filtrate collection, storm water drainage, infrastructure and civil engineering piping, and conveyance piping.

Corrugated Pipe Machine features

- Adopt gear drive.:High speed forming, uniform corrugation, smooth inner and outer pipe wall.

- Use unique screw design: Even heating of raw material, good plasticization and high extrusion speed.

- Closed structure: reduce the interference of external factors, stable production

- Forming module: the module is made of hard steel, CNC processing, with high precision and hardness, guaranteeing stable forming.

- High utilisation rate: double cooling system to guarantee high speed operation and high volume processing requirements.

Why choose plastic extrusion machines?

As a professional manufacturer of plastic extrusion machines, we have extensive experience in the design and installation of extrusion machines and can customise them to suit your requirements.