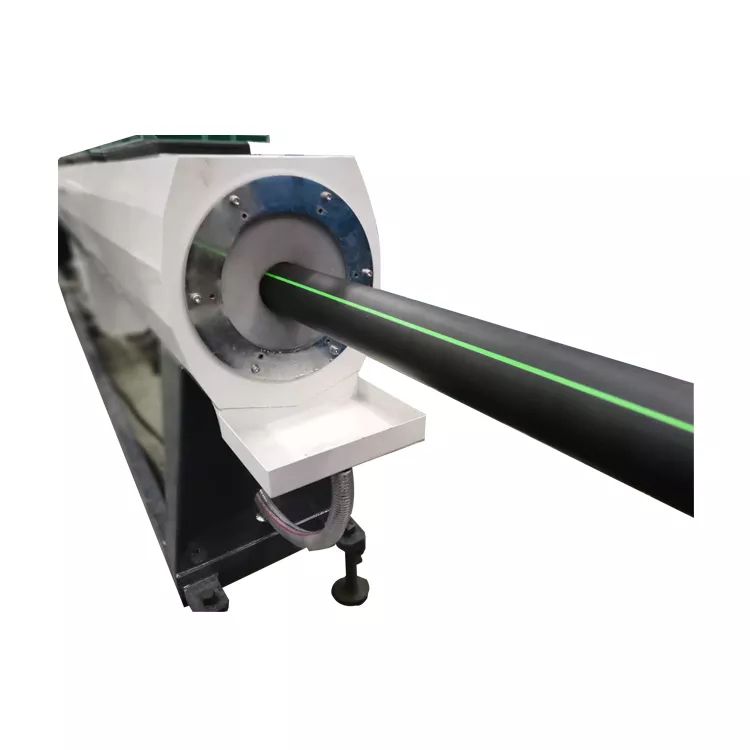

PE Pipe Extrusion Machine

Home » PE Pipe Extrusion Machine

Customised PE Pipe Extrusion Machine

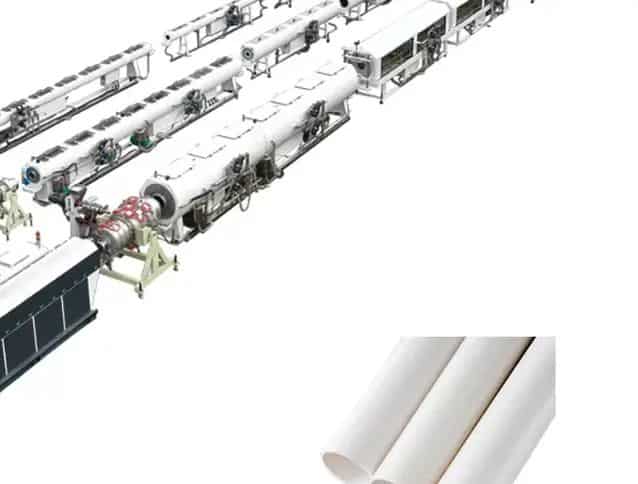

PLASTIC EXTRUSION MACHINES offers a complete turnkey PE pipe extrusion machine, using the most advanced European manufacturing technology for high speed extrusion of HDPE/PE and other polyolefin pipes.

We offer a customised service, selecting the appropriate screw design for each customised material. We meet more uniform and efficient plasticising efficiency, which greatly improves the production efficiency of PE pipe extrusion machine, reduces the production cycle time and fully reduces the labour cost and space cost.

The pipes manufactured are mainly used for municipal pipes, indoor water supply for buildings and water supply for buildings, and meet the needs of pipe processing from 16 to 2000 mm.

Specifications of HDPE Pipe Extrusion machine

PE Water Supply and Gas Supply Pipe Extrusion Line

| Line Type | Diameter(mm) | Extruder | Output(kg/h) | Power(kw) |

|---|---|---|---|---|

| PEG-800 | Ø400~Ø800 | S90/38 | 800-1100 | 585 |

| PEG-1000 | Ø500~Ø1000 | S120/38 | 900-1200 | 650 |

| PEG-1200 | Ø630~Ø1200 | S90/38x2 | 900-1400 | 890 |

| PEG-1600 | Ø1000~Ø1600 | S120/38x2 | 1000-1700 | 1100 |

| PEG-450 | Ø200~Ø450 | S90/38 | 960 | 380 |

| PEG-630 | Ø315~Ø630 | S90/38 | 1050 | 410 |

PE Water Supply Pipe/Gas Pipe Energy-saving and High Speed Extrusion Line

| Line Type | Diameter(mm) | Extruder | Output(kg/h) | Power(kw) |

|---|---|---|---|---|

| PEG-32 | Ø8~Ø32 | 60/38 | 300 | 110 |

| PEG-63 | Ø20~Ø63 double | SS60/38 | 420 | 150 |

| PEG-250 | Ø110~Ø250 | S75/38 | 650 | 230 |

| PEG-450 | Ø200~Ø450 | S90/38 | 960 | 380 |

| PEG-630 | Ø315~Ø630 | S90/38 | 1050 | 318 |

PE production line includes what

- Single screw extruder: this is an important part of the extruder, which plays the role of melting plastic pellets and extrusion molding, and is made of 38CrMoAlA.

- Vacuum calibrated cooling tank: provides a high pressure and stable water jet to maintain the shape of the pipe and the uniformity of the pipe.

- Cooling tank: cools and cures the pipe and moulds it.

- Haul-off machine: pulls the cooled and formed pipe out of the cooling tank and acts as a haul-off

- Cutting: Combined with the PLC control system, the formed pipe is cut to the target length.

- Stacker: collects the tubes of the same length.

- Coiler: Automatic coiling of the tubes to meet the sales needs.

Advantages of PE pipe production line

- Suitable for extrusion of many types of pipes (HDPE/PE and other polyolefin pipes), with specific screw design according to different pipe processing needs. Greatly improve the processing efficiency.

- The whole machine adopts PLC automatic control to achieve integrated closed-loop control, which is convenient for data analysis.

- Adopt European advanced processing technology design.

- It has the characteristics of stable production, high output and wide application.

- Advanced design, beautiful appearance, high degree of automation

- Unique screw design, higher flexibility in processing material selection

- Significant energy saving effect, compare with peer processing effect, energy saving efficiency reaches more than 35%, better economic benefit

Call the pipe extrusion machine experts

Whether you need a small diameter pipe extrusion line for 16mm or a large diameter pipe extrusion machine for 3000mm, PLASTIC EXTRUSION MACHINES is your ideal partner.

Our experienced technical consultants will help to create the ideal HDPE Pipe Extrusion machine for your specific business needs.

Call PLASTIC EXTRUSION MACHINES today for a free consultation on Pipe Extrusion machines or other plastics machinery projects.

Facebook

Twitter

LinkedIn