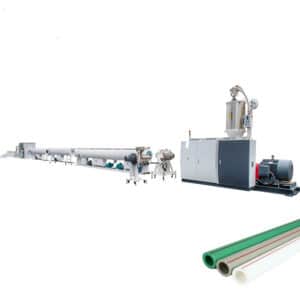

Plastic Profile Extrusion Line

Home » Plastic Profile Extrusion Line

Customised plastic profile extrusion line

The plastic profile extrusion line is dedicated to the production of customised PVC plastic profiles, often used for the production of window and door profiles, beach chair profiles, breeding fence panels, microfoam panels and various decorative panels. The line is equipped with an integrated PLC control system and offers two types of extruders, single-screw and twin-screw, with variable frequency control of the three speeds of feeding, extrusion and haul-off to ensure precision control. The line is characterised by stable performance, high output and good product consistency. On request, we can also provide large-size heterogeneous sheet production lines.

The extruders are available in a variety of sizes.

plastic profile extrusion line Components

The entire block consists of four plates that work in conjunction with each other to complete the sheet production. These include:

- The host extrusion system: by the screw and barrel composition, is the key part of the extruder. Its role is to plasticize the material, quantitative, fixed pressure, fixed temperature extrusion melt

- Transmission system: drive the screw, providing the required torque and torque heating and cooling system: to ensure that the temperature of the plastic and extrusion system in the molding process to meet the process requirements

- Auxiliary machine: head, shaping device, cooling device, traction device, winding device, cutting composition

- Control system: It consists of electrical appliances, instruments and actuators. Its function is to control the main and auxiliary motors to meet the required speed and power; to control the temperature, pressure and flow of the main and auxiliary machines to ensure the quality of the products; to realize the automatic control of the extrusion unit and to ensure the coordinated operation of the main and auxiliary machines.

Model |

Suitable Material |

Extruder Structure |

Extruder model |

Motor poweR |

|---|---|---|---|---|

SJXC |

PP/PE/ABS |

Single screw |

45/28 |

7.5kw |

SJXC |

PP/PE/ABS |

Single screw |

50/30 |

15kw |

SJXC |

PP/PE/ABS |

Single screw |

65/30 |

30kw |

SJSZXC |

PVC |

Twin conical screw |

51/105 |

22kw |

SJSZXC |

PVC |

Twin conical screw |

65/132 |

37kw |

SJSZXC |

PVC |

Twin conical screw |

80/156 |

75kw |

plastic profile extrusion line features

- Automation Design: Increase Work Efficiency, Improve Production Speed And Output, Reduce Labour Costs.

- Optimised Design: Uniform Plasticisation, Low Cutting Speed And Good Product Consistency.

- Increased Co-extrusion Design: Automatic Colouring Of The Profile During The Moulding Process. No Need For Secondary Colouring, Improving Processing Efficiency.

- Processing Performance: Increase The Secondary Processing Treatment Of Wood And Process It Into Target Products At One Time. Increase The Convenience Of Installation.

- Uniformity Of The Product: Adopt Frequency Conversion Differential Design. The Product Is Consistent And Uniform.

Start of customised profile extrusion line

As a specialist plastic extrusion manufacturer, we are capable of producing profile production equipment for a wide range of materials, drawing on our national and international experience in design.