Wood Plastic Composite Machine

Home » Wood Plastic Composite Machine

Customised Wood Plastic Composite Machine

Wood Plastic Composite Machine is mainly used for the production of various architectural decorations. The Wood Plastic Composite Machine is used for the extrusion of PVC/PP/PE/PS/ABS and vegetable fibres. It is often used for the production of doors, flooring, outdoor, packaging panels, building formwork, decoration, outdoor products, wood plastic ceiling decoration and wood plastic wall decoration. This is one of our self-developed and designed products, which can be equipped with embossing device and equipped with integrated PLC control system machinery according to the demand. It has the characteristics of high plasticization, satisfying one time forming, high production efficiency, low energy consumption and long product life.

How about wood plastic composite?

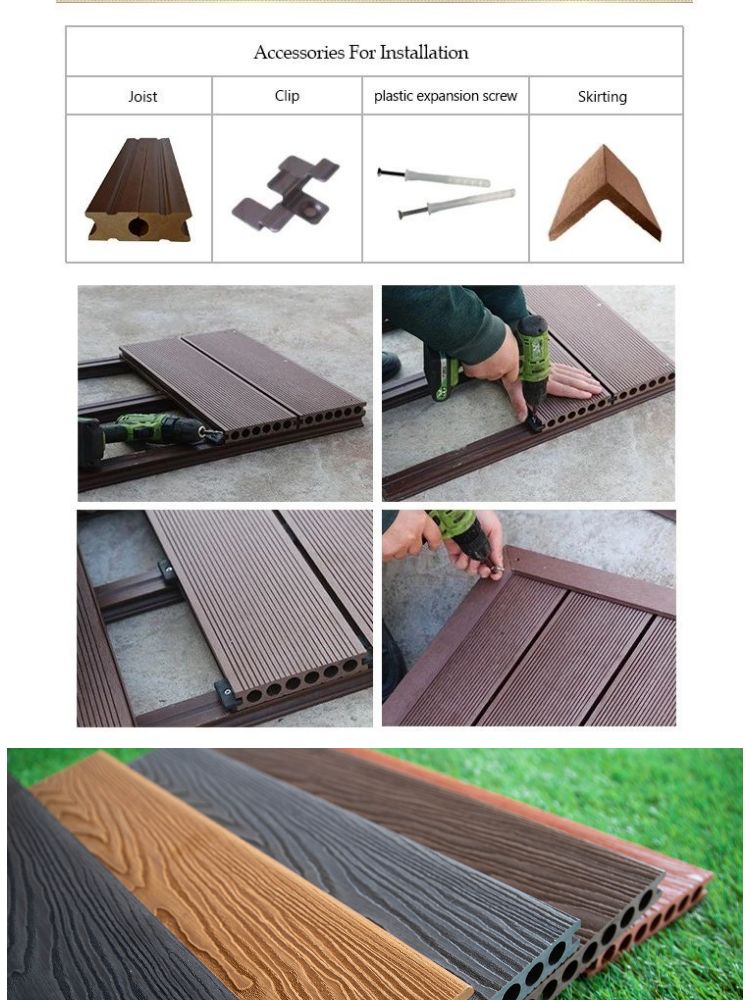

Wood Plastic Composite (WPC) has been used extensively for window and door components, as well as for various decorative purposes such as flooring, decking, landscape timber, table tops etc. WPC flooring is one of the newest construction profiles developed and has a lighter mass and better structure than traditional timber. It can therefore be transported and installed better. It is currently one of the easiest and fastest building profiles to use.

Wood Plastic Composite Machine Components

- Extruders: Special single or twin screw extruders are supplied with hardened gearboxes to provide stable and consistent profile production.

- Moulds: The flow paths of the moulds are designed to provide uniform fluid dispersion and ensure a consistent extrusion rate of the material.

- Vacuum shaping platform: the use of vacuum shaping dies ensures profile shaping degree and speed and reduces the influence of external factors on profile extrusion.

- Haul-off machine: The use of an integral transmission system and a special haul-off fixture increases the stability of the haul-off machine and prevents it from losing step.

- Cutting machine: Pneumatic control is adopted and special fixtures and alloy blades are used to ensure the length of the grommets and the flatness of the cuts when the grommets are cut.

items |

yf180 |

yf240 |

y1300 |

yf600 |

yf900 |

yf1200 |

|---|---|---|---|---|---|---|

Max.width Ofboard(mm) |

180 |

240 |

300 |

600 |

900 |

1200 |

Drawing Height(mm) |

150 |

150 |

150 |

150 |

150 |

150 |

|

Drawing Speed(KN) |

2 |

2 |

2 |

30 |

40 |

50 |

Drawing Speed(m/s) |

0-5 |

0-5 |

0-5 |

0-3 |

0-2.5 |

0-2.5 |

Auxiliary Equipment Sum Power(kw) |

35 |

35 |

30 |

30 |

40 |

45 |

Cooling Water Consume(m'/h) |

6 |

6 |

6 |

9 |

12 |

15 |

Compression air(Mpa) |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

Unique advantages

- Extrusion And Traction Using Integrated Plc Pressure Closed-loop Control: Pressure Increases Traction Speed Up To Ensure Stable Pressure And Traction Fast Pull Off Phenomenon.

- High Efficiency: Good Mixing And Plasticizing, Good Fluidity, Fast Extrusion Speed And High Efficiency.

- High Filling Capacity: Good Mixing And Plasticising, Good Dispersion, High Filling Capacity (70-80% Of Plant Fibre), Low Production Cost.

- Low Energy Consumption: No Drying And Granulation, Significant Energy Saving (compared With Other Equipment Can Save 40%).

- Long Service Life: The Barrel And Threaded Elements Are Made Of Special Materials And Treated Specially, Resulting In A Long Service Life.

- Wide Application: It Can Be Used To Produce Pp, Pe, Pvc, Abs, Ps And Various Plant Fibres. In Order To Improve The Strength Of The Product, Glass Fibre Can Be Added.

Start your customised Wood Plastic Composite Machine

Whether you need a corrugated pipe machine, a plastic tube machine or a hollow sheet machine, as a specialist plastics machinery manufacturer we can deliver. plastic Extrusion Machines is the perfect choice for your plastics machinery. Our experienced technical consultants will help you to create the ideal plastic machinery to meet your specific business needs.