Home » What Is Plastics Extrusion?

What Is Plastics Extrusion?

Plastic extrusion is a continuous mass production process, also often referred to as plasticised extrusion. This process is currently used in a wide range of industries. The most common example is the water pipes we use, which are produced in this way. There are, of course, many other industries that use plastic extrusion, so let’s look at the specific principles of plastic extrusion.

Why choose the plastic extrusion process?

The plastic extrusion process is a high volume production process that increases production efficiency and reduces costs. Because the entire process is carried out in a closed vacuum, there is no waste of raw materials. The raw materials are reused and re-processed. At the same time, it is possible to adjust the process to different product requirements at any time, as the mould can be adjusted at any time, but only for products with the same cross-section, to meet different complex and changing productions.

Principle of the plastic extrusion process

Plastic extrusion is most commonly represented by the PLASTIC PIPE EXTRUSION LINE, manufactured by PLASTIC EXTRUSION MACHINES, which consists of four core components: the feeding zone, the melting system, the cooling system and the extrusion system. The raw material is first fed into the melting system via a feeding system, where it is melted at a high temperature and then cooled in the touch system. The tubes/profiles are drawn out using our additional haul-off system. The profiles are cut to a predetermined length using a PLC automatic cutting system. This is then packaged and sold in bulk.

Why choose the plastic extrusion process?

There are different types of plastic extrusion processes depending on the tooling, so please do not hesitate to contact our engineers if you have any customised requirements.

Tube extrusion

This type of extrusion is usually used for the extrusion production of tubes. In the mould, pressure is applied for forming and curing in a cooling chamber to form the tube to the target diameter.

Blown film extrusion

This type of process die is generally used for the manufacture of products such as plastic bags, which are melted and semi-cured in the die and blown to the required product size and film thickness.

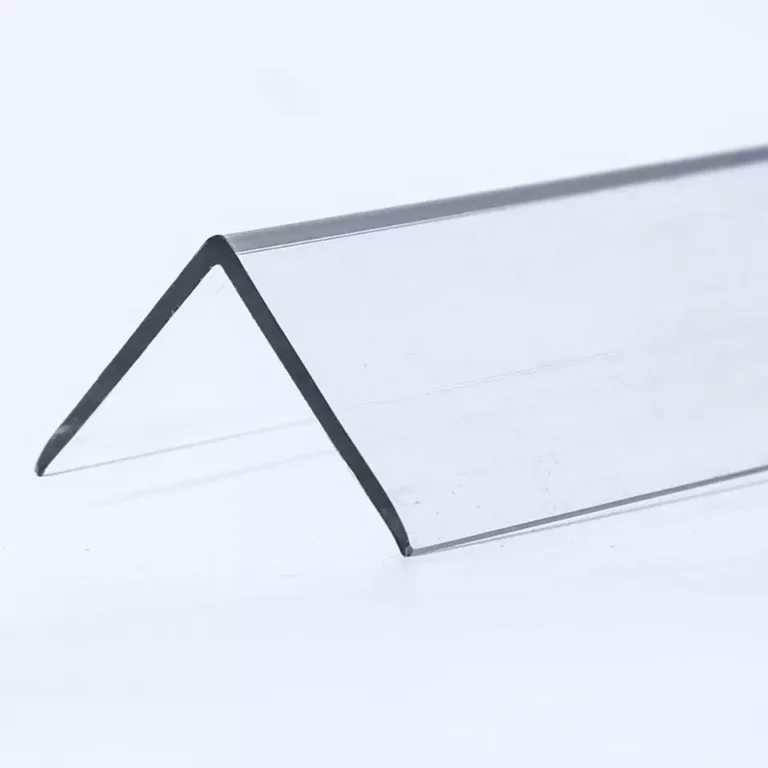

Profile Extrusion

This process is often used to produce specific rectangular sheets and other shapes of extruded material, most commonly the PLASTIC PROFILE EXTRUSION LINE, where the material is extruded and moulded.

How to choose plastic extrusion equipment?now

Since, the plastic extrusion process is so important to a company’s production as well as its operations, it is especially important to choose professional plastic extrusion equipment. With all the different types of plastic extrusion equipment on the market today, it is particularly difficult to choose a machine that is stable and yet professional in its performance. As well as this is our project advice.

Firstly, what is the product you need to determine to produce? Is it a pipe or a sheet, the corresponding die and screw will have corresponding differences.

Secondly there are the differences in processing materials and the choice of different processing equipment depending on the application. For example, PVC as a harmful plastic substance, as the production of water pipes is obviously not, then you need to choose other non-toxic non-hazardous materials, such as HDPE.

The last thing is the qualification of the company chosen. The plastic extrusion process is also constantly being optimised and developed, and the latest equipment corresponds to different production efficiencies, especially in the rapidly developing industrial age, where production efficiency determines how much profit a factory makes. PLASTIC EXTRUSION MACHINES, as a professional Chinese manufacturer with independent research and development capabilities, is currently matched with professional technical engineers to constantly upgrade and optimise our extrusion range. We are constantly improving the overall efficiency of our extrusion machines while maintaining stability. We have received many positive feedbacks from our customers.

Related articles

As the performance requirements of piping systems for construction and industrial projects continue to...

A corrugated pipe is a type of pipe with a corrugated structure, usually made of HDPE, PVC, steel and...

PVC piping is one of the key indispensable materials in modern construction and industrial projects....