What Is Plastic Extrusion?

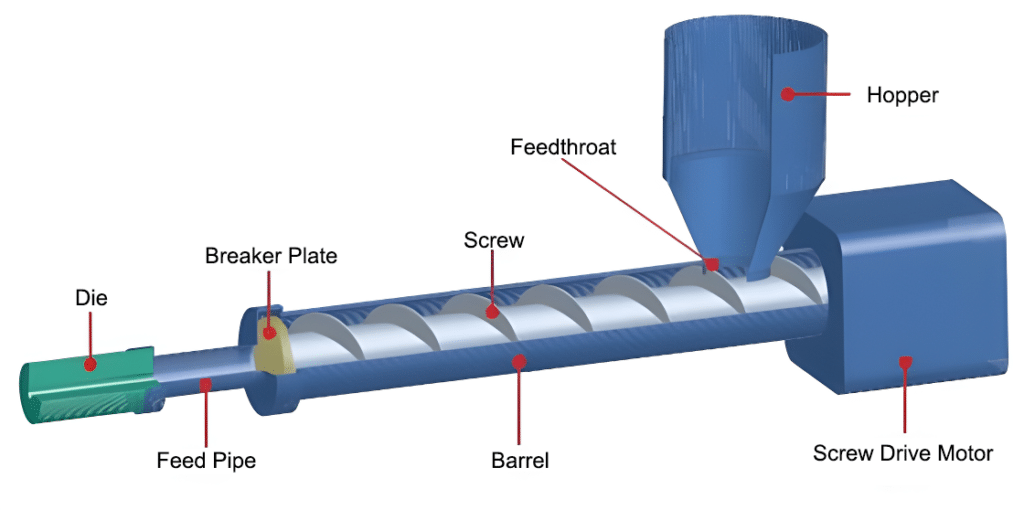

- Hopper:This is part of the extruder that holds the powdered, pelleted, or chopped material for the plastic extrusion process.

- Feed-Throat:This part of the extruder connects the barrel to the hopper. In other words, it helps move the material from the bin to the barrel so that it can be used in the plastic extrusion process.

- Breaker Plate:The breaker plate helps keep the pressure up. It also acts as a screen to keep things from getting into the barrel that shouldn’t be there.

- Barrel:This part softens the plastic by applying heat, getting it close to its melting point. It also holds the rotating screw, which provides the pressure needed to force the plastic material down the feed pipe.

- Feed pipe:The barrel is connected to the die by this pipe. In other words, it moves the molten plastic from the tube to the die.

- Die:Here is the part where the mixed heated material leaves. The mold is usually made of metal and it serves to give the processed material a specified profile.

- Cooling System:In this part, the processed plastic cools quickly, which helps it harden.

How Does Plastic Extrusion Work?

Earlier we learned what the plastic extrusion process is. So, next, let’s learn more about how plastic extrusion machines work. This process is divided into four main steps.

Step 1: Putting in the ingredients

The first step in the process of extruding plastic is to add additives to the plastic that will be used. Of course, it is not at all like CNC cutting. Depending on what needs to be made, the additives could be colorants or UV inhibitors.

Step 2: The material starts to melt

Step 3: Putting the shape together

As the spinning screw pushes the molten material out of the barrel, it goes through one or more screens at the barrel’s end. These screens do two important things at the same time.

First, it cleans the molten plastic by getting rid of any alien objects or other impurities. Second, it helps make sure that the pressure stays the same throughout the system by offering the same amount of force everywhere. So, when the liquid material goes through the screens, its temperature goes up a lot and it becomes easier to shape.

By pushing the melted plastic through the die, then you can get the shape you want. This means that the shape of the liquid plastic will be the same as the shape of the die.

Step 4: Let it cool down

Related News

PVC Vs Corrugated Drain Pipe

Drainage systems are a critical part of residential and industrial projects. The right choice of pipe not only affects the overall efficiency of the project, but also determines the system’s

How Is Pvc Pipe Made?

PVC piping is one of the key indispensable materials in modern construction and industrial projects. When it comes to choosing the right piping material, PVC piping has become the standard

What Is Corrugated Pipe?

A corrugated pipe is a type of pipe with a corrugated structure, usually made of HDPE, PVC, steel and other materials. Its surface consists of longitudinal ridges and grooves, making